Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang

Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang Detail:

Ni-Cr electrothermal alloy has high temperature strength. It has good toughness and does not easily deform. Its grain structure is not easily changed. The plasticity is better than Fe-Cr-Al alloys. No brittleness after high temperature cooling, long service life, its easy to process and welding, but the service temperature is lower than Fe-Cr-Al alloy. Ni-Cr electrothermal alloys are one of the main products of our company. All resistance heating alloys manufactured by our company are distinguished by uniform composition, high resistivity, stable quality, accurate dimension, long operating life and good processability. Consumers can select the suitable grade according to different requirements.

Steel grades and Chemical composition(GB/T1234-1995)

|

Steel grades |

Chemical composition(%) |

||||

|

|

C |

Si |

Cr |

Ni |

Fe |

|

Cr15Ni60 |

≤0.08 |

0.75-1.6 |

15-18 |

55-61 |

- |

|

Cr20Ni30 |

≤0.08 |

1-2 |

18-21 |

30-34 |

- |

|

Cr20Ni35(N40) |

≤0.08 |

1-3 |

18-21 |

34-37 |

- |

|

Cr20Ni80 |

≤0.08 |

0.75-1.6 |

20-23 |

remain |

≤1 |

|

Cr30Ni70 |

≤0.08 |

0.75-1.6 |

28-31 |

remain |

≤1 |

(According to the needs of customers, we can provide alloys in accordance with the enterprise standards, such as American standard, Japanese standard, German standard and other standards)

Properties and Applications

|

Steel grades |

Max.continuous operating temperature℃ |

Tensile strength N/mm2 |

Elongation at rupture(approx.)% |

Electrical resistivity μ·Ω·m |

|

Cr15Ni60 |

1150℃ |

700-900 |

>25 |

1.07-1.20 |

|

Cr20Ni30 |

1050℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni35(N40) |

1100℃ |

700-900 |

>25 |

0.99-1.11 |

|

Cr20Ni80 |

1200℃ |

700-900 |

>25 |

1.04-1.19 |

|

Cr30Ni70 |

1250℃ |

700-900 |

>25 |

1.13-1.25 |

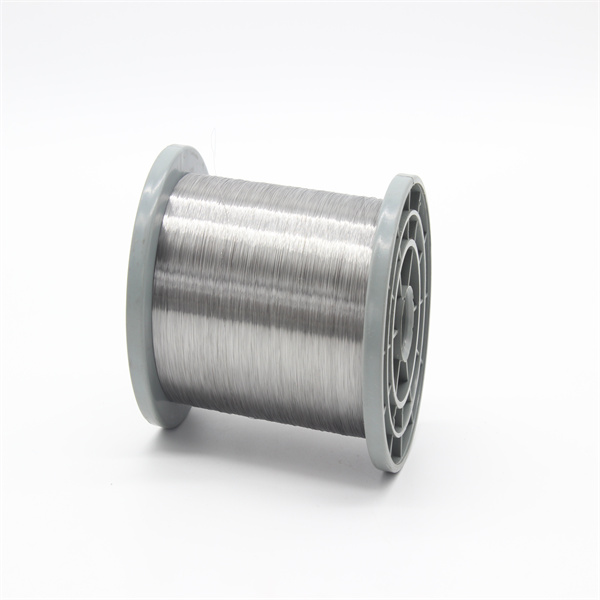

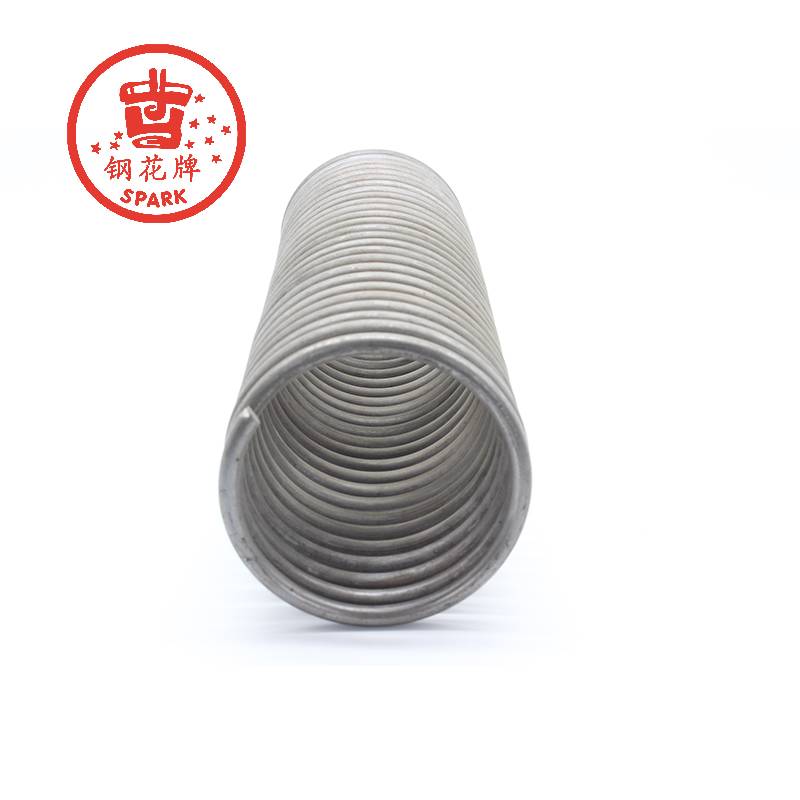

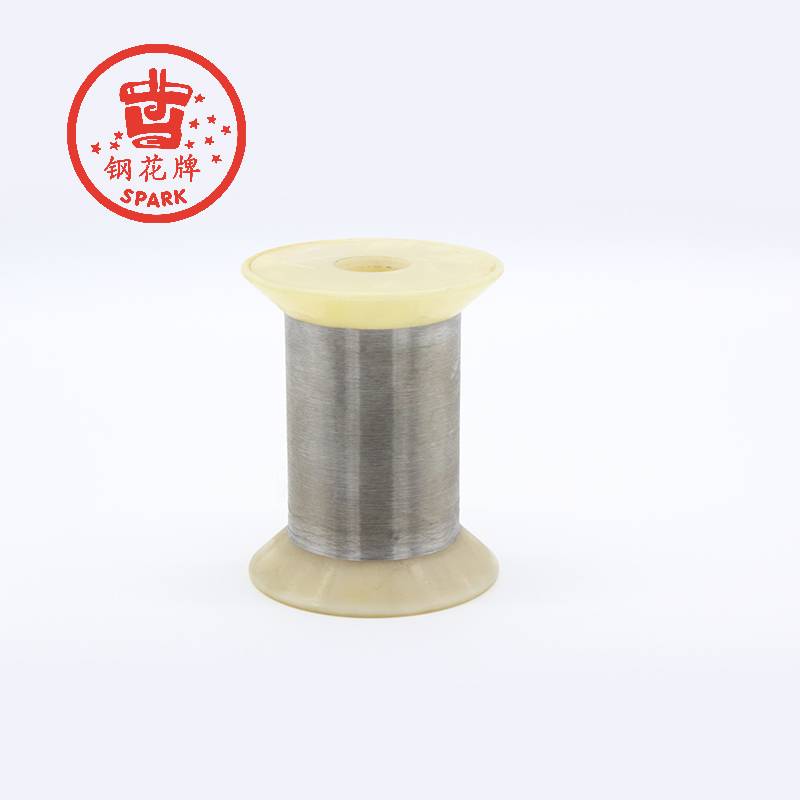

Size range

|

Wire diameter |

Ø0.05—8.0mm |

|

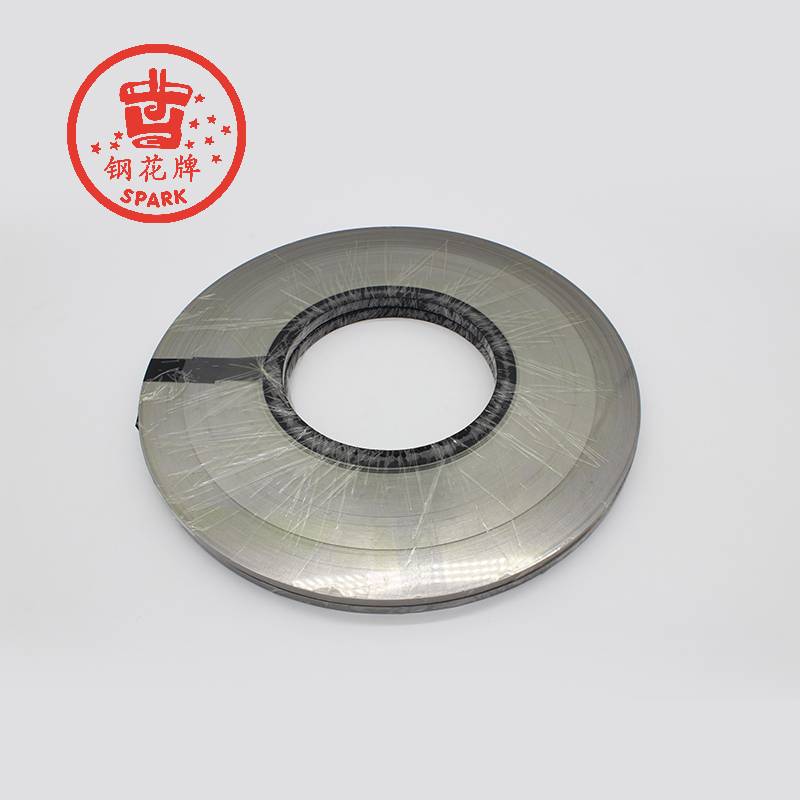

Ribbon |

Thickness 0.08—0.4mm |

|

|

Width 0.5—4.5mm |

|

Strip |

Thickness 0.5—2.5mm |

|

|

Width 5.0—48.0mm |

Product detail pictures:

Related Product Guide:

Our business promises all users of the first-class items and the most satisfying post-sale company. We warmly welcome our regular and new prospects to join us for Good quality FE CR AL High Heat Electrical Wire - Ni-Cr alloys – Shougang , The product will supply to all over the world, such as: Vancouver, Germany, Adelaide, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!