OEM/ODM Manufacturer Aluminium Alloy Welding Wires - Thin Wide Strip for glass top hot plates – Shougang

OEM/ODM Manufacturer Aluminium Alloy Welding Wires - Thin Wide Strip for glass top hot plates – Shougang Detail:

Nowadays,induction cookers and traditional light wave cookers have become main electrical stove in kitchens. Induction cookers can’t continuously work on the condition of small fire, with which the electromagnetic wave harmful for people is radiated.Because of the low heat quantity applied by traditional light wave cookers,their temperature rise too slowly to fry quickly and waste too much energy. To make up for the deficiency of cooker, a new cooker product for advanced glass top hot plates has been developed at home and abroad.

As a professional company researching the electrical heating alloy,we have designed special thin wide strip for heating components of glass top hot plates.

Steel grades and Chemical composition

|

Steel grades |

Chemical composition% |

||||||

|

|

C |

Si |

Cr |

Al |

S |

P |

rare earth element |

|

0Cr20Al6 |

≤0.03 |

≤0.4 |

19-21 |

5.0-6.0 |

≤0.02 |

≤0.025 |

Appropriate amount |

Size range

Thickness:0.04-0.1mm±4%

Width:5-120mm±0.0.5mm

Properties

|

Steel grades |

Maximum service temperature |

tensile strength(N/mm²) |

Elongation% |

Electrical resistivity |

|

0Cr20Al6 |

1300℃ | 650-800 | >12 |

1.45±0.05 |

Based on good plasticity of the alloys,they have excellent cold working formability. The alloys’ resistance fluctuation is small,and the value of resistance per meter is no higher than four percent, which cause that the alloys are beneficial in even heating. The trace element addedin the alloys promote oxide film fixed with the body to form in heating process, that improve the alloys’ oxidation resistance at elevated temperature. With the help of trace element, creep resistance is greatly improved at high temperature. The products have not being deformed after elevated temperature for a long time.

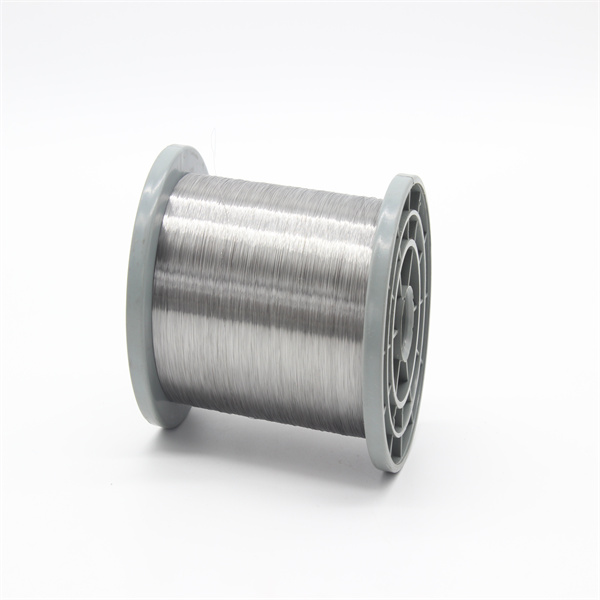

Product detail pictures:

Related Product Guide:

We always continually offer you the most conscientious purchaser services, and the widest variety of designs and styles with finest materials. These efforts include the availability of customized designs with speed and dispatch for OEM/ODM Manufacturer Aluminium Alloy Welding Wires - Thin Wide Strip for glass top hot plates – Shougang , The product will supply to all over the world, such as: Libya, Mongolia, United Arab emirates, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.